Innovation of photobioreactor for microalgae by using fluid dynamics and proposal of

its usage for CO2 fixation

Sato T.1, Usui K.1, Nakatsuka N. 1,

Sakurai S. 1,

Tsuchiya Y. 1, Kondo Y.2, Hirabayashi S.3

1University of Tokyo, Tokyo, Japan

2Yamaha Motor Co. Ltd., Iwata, Japan

3Micro Gaia Inc., Maui, USA

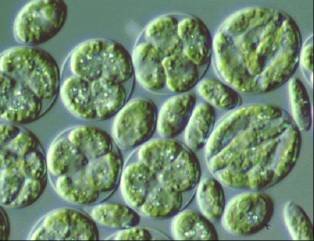

It

has been said that the fixation of carbon dioxide by using microalgae is one of

promising methods to reduce the so-called greenhouse effects. For this purpose,

it is necessary to innovate high-performance photobioreactors for

mass-production use. However, it seems not-so-easy to attain the productivity

accomplished by laboratory-scale reactors. This is partly due to the thickness

of reactor chambers and high concentration of algae, which are simply for

accommodating necessary volume of cultivates in a reasonably economical

mass-production system, but prevent the algae from receiving sufficient

sunlight and the cultivate medium from mixing nutrients and dissolved gasses

equally.

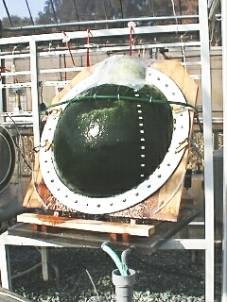

We focused on the Bio-dome

developed by one of the authors (SH), which is a discrete-type reactor for mass

production and was adopted for commercial use recently. Firstly, the flow in a

Bio-dome was elucidated by using flow-visualization techniques. Then, the shape

of a photobioreactor was analyzed. We classified its functions into three, i.e.

sunlight-reception, global mixing, and local mixing. While the first and third

were mathematically modeled, the second was numerically simulated by using

two-phase CFD (computational fluid dynamics). Here we were interested in the

third function of photobioreactors; the local mixing, in other words, vortices

mixing algae in the thickness direction of a reactor chamber. Our mathematical

model for the dark-light cycle for photosynthesis can predict the increase of

productivity by intensifying these vortices, although the model needs further

investigation to acquire sufficient accuracy.

Next, we tried to innovate

novel forms of photobioreactors. It is important for mass production that the system

of reactors must be simple. Our design policy is that steady flow should

provide algae with equal opportunity for sunlight, nutrients, and dissolved

gases. Apparatus for unsteady flow, which is regarded as effective to reduce

unfairness among algae in terms of sunlight-reception, sometimes cause small

troubles. However, this is serious, if small, for mass production using numbers

of discrete reactors. To select better shapes of reactor chamber, the CFD code

was used to evaluate the global mixing performance. Here we introduce two

parameters; deviations of random numbers initially set in each cell of

computational mesh and of light intensity added in each cell at every

computational time-step depending on the distance from the reactor surface.

Another kind of selection was done in terms of the sunlight-reception

capacity. Two types, which had

survived through the above selections, were manufactured and tested by using Chlorococum littorale for the 12 mostly

clear winter days in Iwata. The winner of this last selection performed

0.15g/L/day (6.8g/m2/day) at the alga-concentration of 1-2.5g/L,

that is 57% more productivity than the Bio-dome.

Lastly, we consider proposing

a reasonably economical CO2 fixation system by using high-performance

photobioreactors (0.5g/L/day, 24g/m2/day) and Botryococcus braunii. The system is supposed to be constructed in

the Hobuqi Desert in China, using water from the Huang He River and exhausts

from a coal power plant in Paotou City. Our calculation shows that the total

CO2 fixation cost is about 100yen($0.8)/kg-CO2. The reduced CO2 is the one

supposed to be exhausted from current Chinese power generators burning coal,

which is replaced by Botryococcus braunii

as biomass fuel. Here, the exhaust gas from the coal power plant is directly

lead to the photobioreactors, so that the used Botryococcus braunii should be genetically manipulated to endure

sulfuric acid and nitrogen oxides.

References:

1. Terry, K.L.

(1986) Photosynthesis in modulated light: quantitative

dependence of photosynthetic enhancement on flashing rate, Biotech. Bioeng. 28:988-995.

2. Jones, R.W.

(1999) Mass transfer in a bubble column photobioreactor, Biotech. Bioeng.

76:1345-1351.

Chlorococum Littorale

Photo-Bioreactors

Computer Simulations